Advanced Assembly Equipment Improves Efficiency and Quality in FI Relay Production

At ETI, we're continuously driving innovation to enhance the precision, efficiency, and reliability of our production processes. One of our most recent achievements in this journey is the new assembly and welding machine for magnetic systems used in FI relays—a solution that brings us closer to a smarter, more controlled manufacturing future. This project has also been awarded a national award for innovation from Chamber of Commerce and Industry of Slovenia.

| Jakob Jesenšek |

From Concept to Reality: A Joint Development Effort

Developed in close collaboration with Titus Technologies, the new machine is the result of 18 months of research, development, and optimization. The goal was to replace the existing device with a system that meets higher quality standards and increases efficiency through full automation and smart quality control.

By building on the strengths of the previous machine and incorporating missing functionalities, we created a highly optimized solution. Titus supported the process with prototype samples for testing and parameter fine-tuning based on real-world performance.

Inside the Machine: How It Works

The device features two rotary tables, each with multiple workstations performing sequential tasks at a cycle time of just 4 seconds—a significant leap in throughput.

Small Rotary Table (4 stations):

Copper foil cutting

Laser welding of foil to the L-yoke

Air cleaning of the workstation

Transfer of the subassembly to the large rotary table, with optical inspection of position, cut, and foil presence

Large Rotary Table (12 fixtures, subdivided into A, B, and C modules):

In Module A, a magnet is inserted and aligned with the L-yoke using pneumatic cylinders, followed by laser welding.

In Module B, the S-yoke is automatically inserted and welded to the L-yoke + magnet. Visual inspection checks weld quality and geometry.

In Module C, the assembled subassembly is transferred via robot arm to the final measurement station, where precise dimensional checks determine if the product meets quality standards.

Good parts continue to the output conveyor; non-compliant parts are sorted out automatically. This process eliminates the need for manual inspection, which was the bottleneck in the old system.

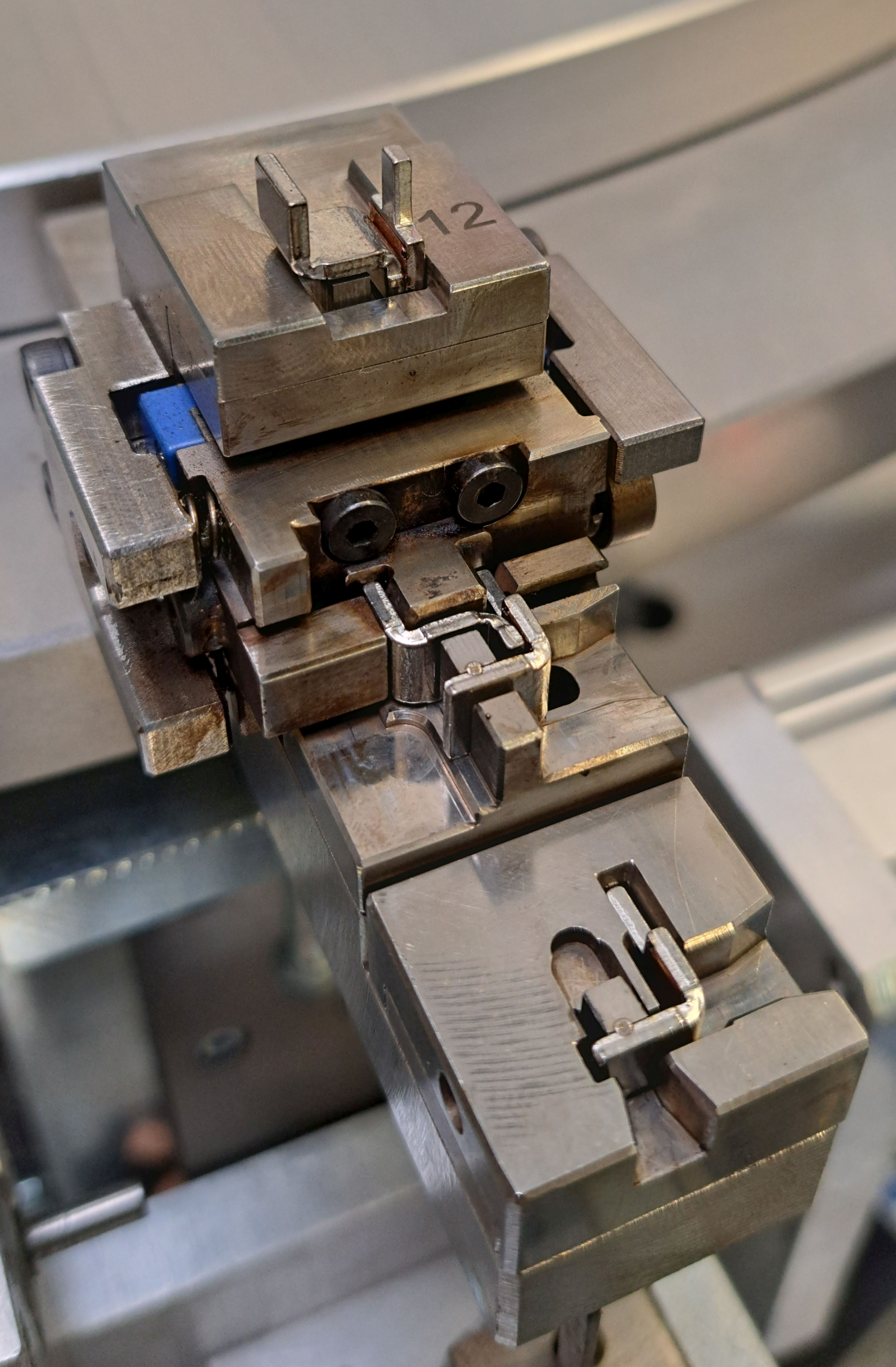

Insert for assembling magnetic systems

Smarter Quality, Faster Feedback

Unlike the previous machine, which required manual and sample-based measurements, the new solution offers:

Full in-line measurement of every assembled subcomponent

Real-time data and traceability

Immediate rejection of faulty units

Automated calibration (etaloniranje) of the measuring station to ensure ongoing accuracy

This level of quality control allows us to catch and correct issues early, while also gathering valuable production data for continuous improvement.

Automatic control of finished products

Supporting Long-Term Reliability

To ensure stable performance, the process includes a demagnetization cycle every 2 hours, reducing the risk of magnetized components interfering with downstream assembly. It's just one more way we’re safeguarding process consistency and reducing material waste.

What This Means for ETI

This innovation supports our long-term strategy of production automation, quality assurance, and customer satisfaction. It aligns with our commitment to safe, reliable electrical solutions—and ensures that our FI relays remain a trusted component in protection systems worldwide.

With this new solution, ETI is once again proving that innovation is not just about new products—it's also about smarter processes, tighter control, and better results.