The Vital Role of Contactors

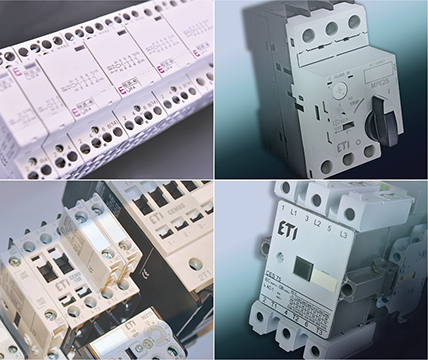

In the realm of electrical systems, there is a key component that often goes unnoticed but plays a vital role in motor control. It is the contactor - a seemingly modest device with extraordinary capabilities. From regulating power supply to ensuring smooth operation, contactors are the unsung heroes of electrical distribution. We delve into the intriguing world of contactors, shedding light on their functionality and uncovering the crucial role they play in optimizing motor control. Join us on this journey as we unveil the power and precision behind contactors.

Introduction:

In this blog post, we'll explore the essential functions and features of contactors, shedding light on their significance within electrical distribution systems. Get ready to uncover the secrets behind these versatile devices and discover how they enable smooth and efficient motor operations.

Motor control gear, including contactors and overload relays, forms the backbone of electrical distribution systems. At its core, a contactor is a crucial switching device, working in tandem with other components to regulate the power supply to motors. By understanding how contactors operate, we gain insight into the mechanics of motor control.

Contactor: The Switching Device

Imagine a world where electrical circuits come to life, where a magical switch with electromagnetic powers takes center stage. Enter the contactor, the superstar of motor control gear. This contraption consists of contact assemblies brought to life by electromagnetic sorcery. When its operating coil is energized, an armature latches onto a set of moving contacts, sparking a connection with a set of stationary contacts.

Material Selection and Design Considerations:

Contactors employ carefully selected materials for their contacts, ensuring optimal performance and longevity. Modern contactors utilize silver alloy contact tips, such as silver-cadmium oxide or silver-tin oxide, which exhibit excellent resistance to welding and erosion. The design of the contacts, typically featuring double-break main contacts, further enhances electrical conductivity and minimizes wear.

Arc Control and Extinction:

Effective arc control is critical for optimal contactor performance. Smaller contactors benefit from the inherent characteristics of the a.c. supply, such as natural current zeros and contact opening, which aid in arc suppression. Larger contactors often incorporate cooling plates or de-ion plates within their arc chambers to facilitate arc extinction, ensuring safe and reliable operation.

Balancing Speed na Durability:

Contactors are designed to extinguish the arc quickly to ensure durability and prolonged service life. Typically, the arc should be extinguished within 10-20 milliseconds during type test conditions and 5-10 milliseconds in normal operation. Modern contact designs can achieve a contact life of 1-2 million operations.

How it works:

Contactors operate through a simple yet effective mechanism. They are magnetically held closed by maintaining the current flow through an operating coil. When the coil is energized, it generates a magnetic field that attracts an armature, which is connected to a set of moving contacts. These moving contacts come into contact with a set of stationary contacts, allowing the current to flow through them and power the motor.

Selecting the Right Contactor:

Choosing the appropriate contactor involves considering factors such as the AC3 rating, which indicates the switching capability for cage type induction motors. Other utilization categories, like AC4 and AC2, cater to specific motor control scenarios. Additionally, factors like ambient temperature, rate of operation, and short-circuit protection requirements influence the selection process.

Conclusion:

Contactors are essential components of motor control gear, providing reliable switching and control of motors. Their construction, materials, and design are optimized to ensure efficient operation and durability. By understanding the significance of contactors and considering the appropriate selection criteria, engineers and designers can ensure the safe and effective functioning of motor control systems.

Remember, proper selection and utilization of contactors contribute to the overall efficiency and reliability of motor control gear.